Composite Service

With leading expertise in composite design and manufacturing, we deliver attractive solutions in both existing and new application areas

LATEST UPDATES

Innovative products who save both money and the enviroment

We manufacture and supply composite products to many different industries in healthcare, vehicles & aerospace

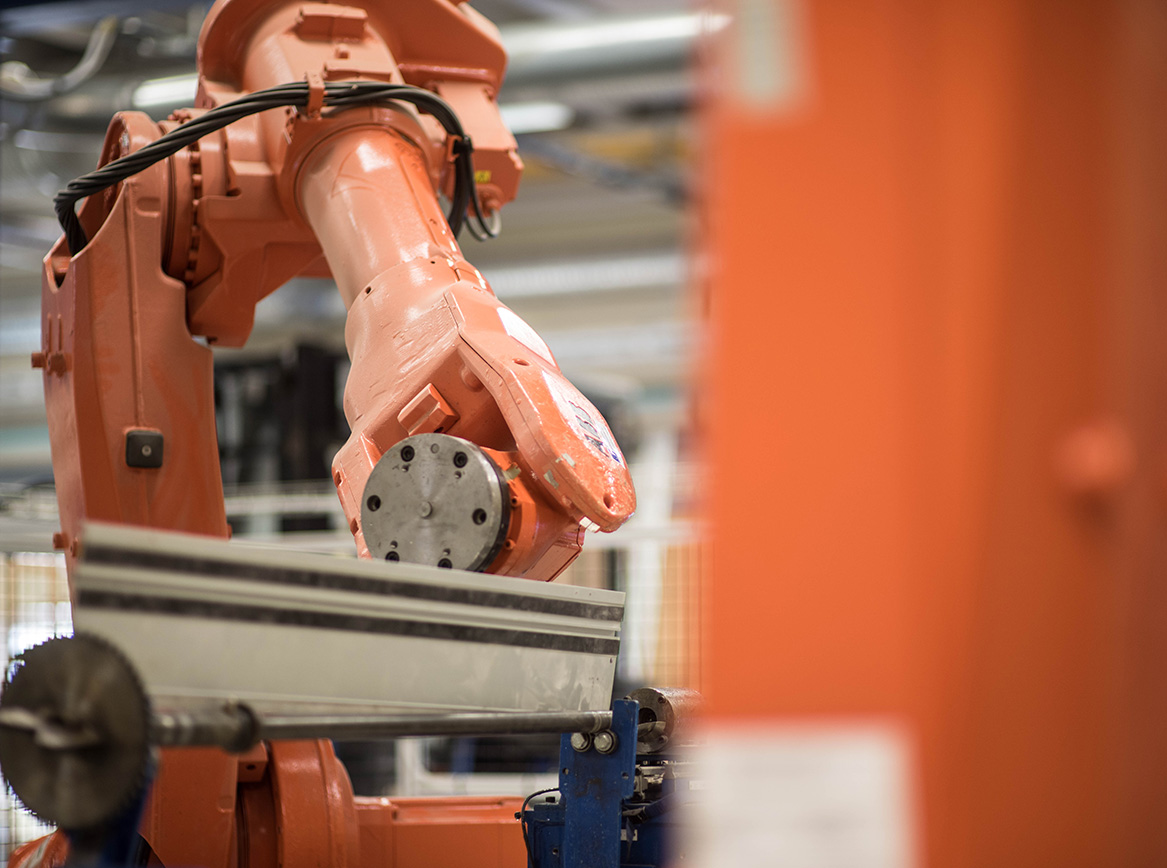

Source: Kuka Automation

We offer new solutions to old problems

We want to combine our knowledge in composite manufacturing and our long experience of pressurized devices to find applications in new areas. With the environment in focus, we have identified areas where we can offer attractive solutions.

Industrial leader in composite manufacturing

Installation and commissioning worldwide Extensive experience of service and international support, CAD/CAM and design knowledge

Source: Huddig

Contact Form

Meet The Team